Technical Department Scope of Business

Tank cleaning works & services.

Underwater inspection and hull cleaning.

Technical stores, spare parts supply and installation.

Holds cleaning including lime wash arrangements

Supply and Maritime Logistics Scope of Business

Catering services.

Husbandry agency services.

Liquid waste removal and de-slopping.Garbage disposal services.

Off-shore Industry Services Scope of Business

We have the concept of tailored services made specially to serve different segment of off-shore industry.

Tank Cleaning Works & Services

Overseas is fully aware of how essential and demanding the tank cleaning

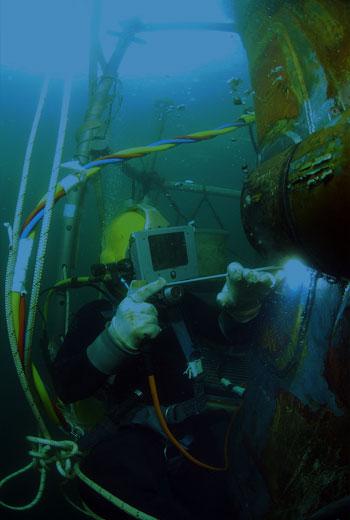

Underwater Inspection and Hull Cleaning

Overseas is always keen on building and maintaining trust with its customers from ship owners, managers to ship agents

Technical Stores, Spare Parts Supply and Installation

We supply a wide selection of technical, industrial and navigation stores for the marine industry ranging from mooring ropes and wires to marine paints and tools to electrical spares.

Holds Cleaning Including Lime Wash Arrangements

Our decision-making speed and one-point-of-contact are essential to ensure quick response time by our cleaning experts who also handle your inquiry.

Ship Repair & Maintenance Services

We provide services for classification, damage repair, modifications, preventive maintenance and (sale) inspections.

Catering Services

High quality provisions and services are the fundamental factors to boost crew productivity and morale.

Husbandry Agency Services

We do promise to provide you with a tailor-made solution for your husbandry needs.

Liquid Waste Removal and De-slopping Garbage Disposal Services

Ship sludge discharge involves careful planning and execution to ensure environmental safety.